DNP ENCAPSULANTS

DNP Encapsulant materials are designed to provide excellent protection over a long lifetime to photovoltaic modules, giving a high transmission under use as well as ease of handling in production for module manufacturers.

We have divided our Encapsulant sheets into two main families:

Encapsulants suited for crystalline PV modules

Encapsulants suited for thin film PV modules

Each of the Encapsulant sheets has been engineered in the DNP laboratories in order to address specific solar module applications.

Compared to normal EVA-type of encapsulants the engineered dnp products offer much better performance in terms of adhesion strength and durability under damp heat test (water vapor permeability) as well as a drastically increased insulation with excellent resistivity. Furthermore there is no acid gas production from the DNP Encapsulants as well as it should be noted that lamination of the DNP Encapsulants require no curing and thus enables fast and efficient production flow of the PV Modules. Finally the long potential shelf life provides our customers with increased flexibility in production.

Product Advantage

- High water vapour barrier

- High reliability without by-product of cross-linkage

- Low efficiency reduction without generating gas

- High transmittance

- Good adhesion to glass and backsheet

- Long shelf-life

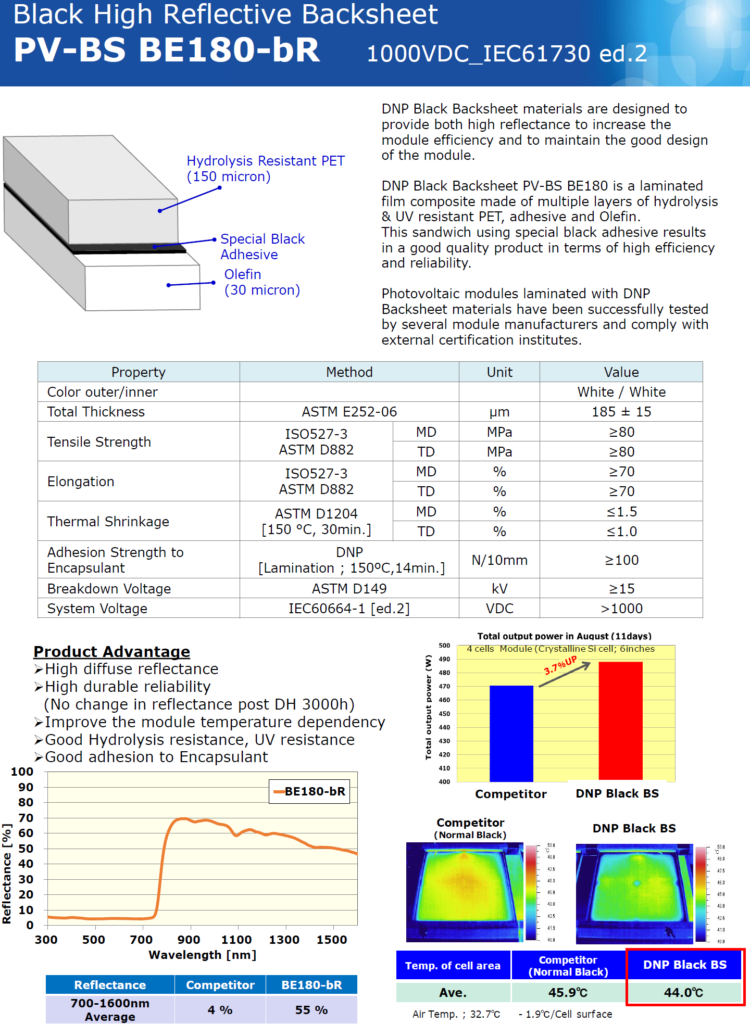

BACKSHEETS

DNP Back Sheet materials are designed to provide excellent protection over a long lifetime to photovoltaic modules and ease of handling in production for module manufacturers.

We have divided our back sheets into 3 main families:

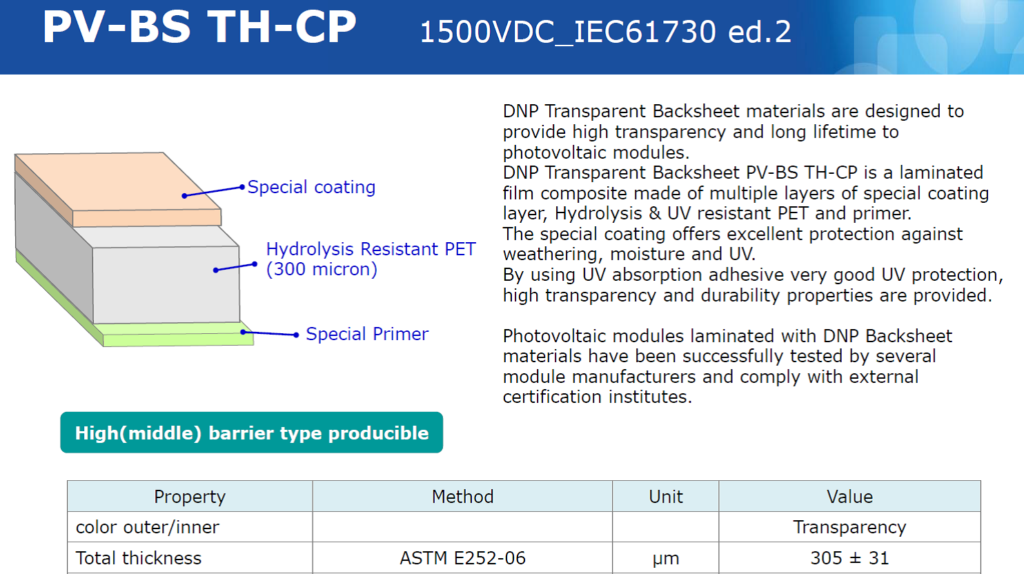

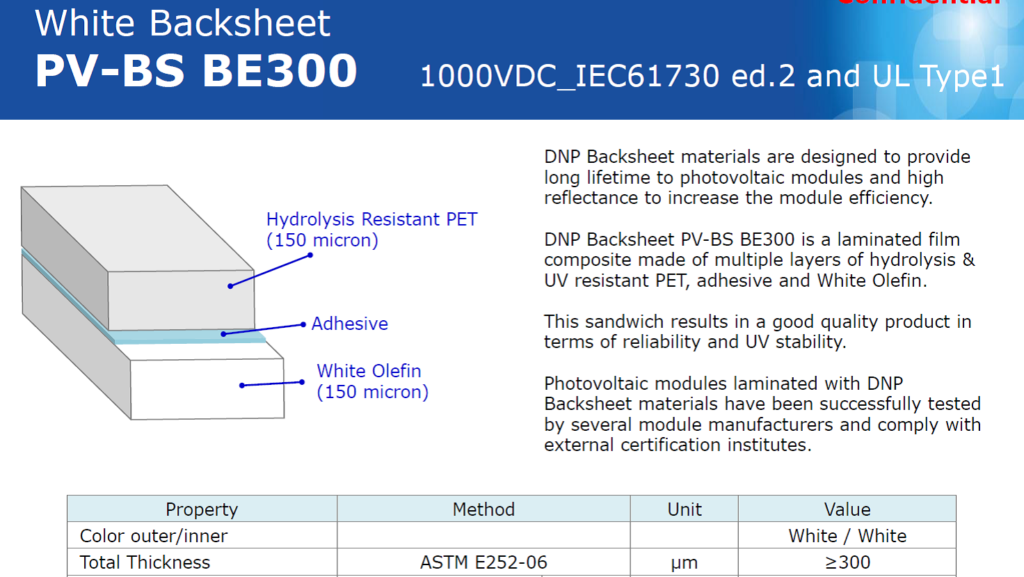

The PET type:

The PET type of back sheet comprises a speciality layer of hydrolysis & UV resistant PET, and a normal layer of PET combined with one layer of Poly Olefin. This sandwich results in a good quality product in terms of reliability and UV stability meeting all requirements set forward by IEC standards.

The Fluoric type:

The Fluoric type of back sheet comprises one layer of ETFE and one layer of PET combined with one layer of Poly Olefin. This sandwich results in a high quality product that provides excellent reliability in terms of durability and hydrolysis in combination with high reflectance in order to increase module efficiency and supreme UV stability.

The High Barrier type:

The High Barrier type of back sheet comprises a speciality layer of hydrolysis & UV resistant PET, one layer of aluminium, one layer of normal PET combined with one layer of Poly Olefin. This sandwich enables a first class protection of the module with absolutely no water vapor permeability, high durability and excellent UV resistance.